We are specialize in polyurethane (PUR) product manufacturing.

In 2005, our company certified quality

management system ISO 9001:2000 and

in 2008 company certified the

quality management system ISO/TS 16949:2002.

Our purpose is:

To improve the quality of products, to meet all customer

requirements and to expand product assortment.

"HCV-Design"

have the possibility to develop new moulds.

We are over 30 years in seating development and production of industry seating till car-seat projects.

Polyurethane cushions, from developing till production of your own seating program or any foam product you need.

Out of

viscoelastic polyurethane we produce protectors for motorbikers.

The

material is very good in energy absorbing. Our protectors are

approwed as

one of the best in world.

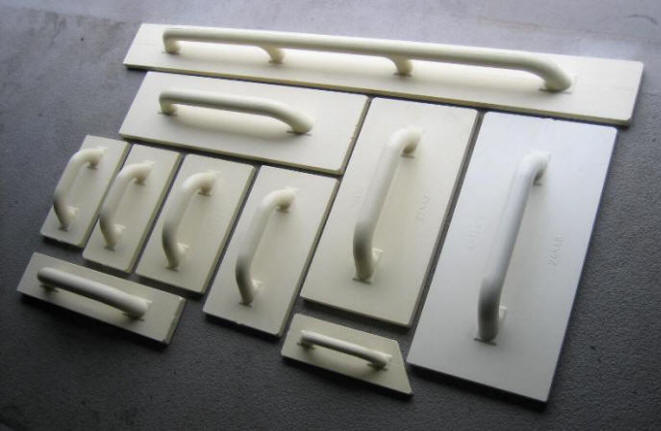

Out of hard integral polyurethane, we can

also produce the tools for the

construction workers.

injection mould

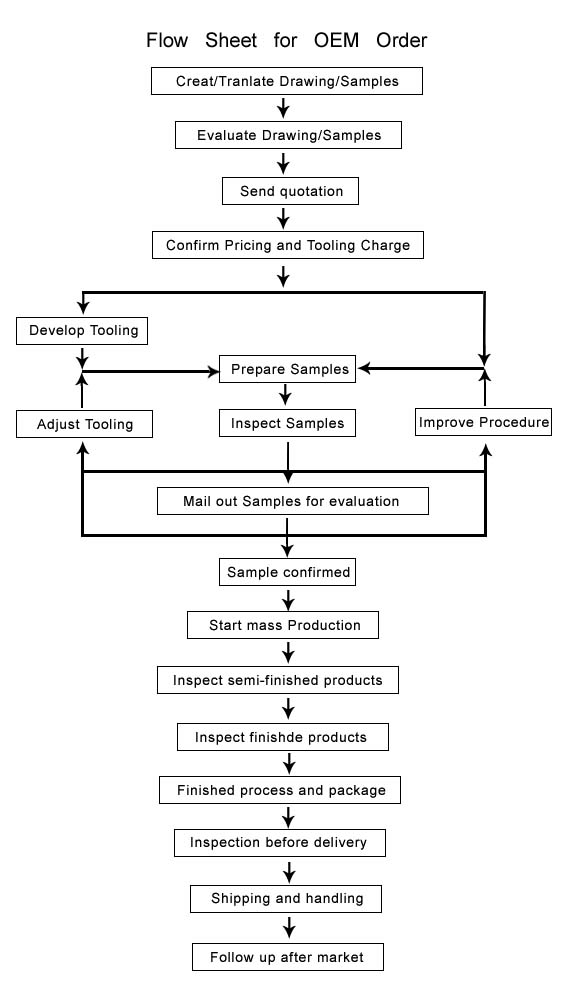

An ISO9001:2000 plastic injection molder, would like to help you

start the new project with

Competitive Price, High

Quality, Fast Delivery, Best service.

It is our honor to take this opportunity to share our

information with you.

certified in ISO 9001, 14001 and 18000 Quality

Systems, qualality is always our highest priority.

On every mold making process to make sure we delivery

the best quality mold.

Online project tracking system. Help

you control the whole project and let you

have the feeling

that moulds/products are built in your own house.

Porfessional engineers team will provide you with

professional project suggestion for your

mold

and part design, we fully support our customers during the

pre-production, production start-up.

And full production phases of every project apply its

expertise to review your design to identify

any potential

benefits or cost savings.

One stop

solution for

your project need, we offer a variety of value-added

operations

to

complete your injection molded products, including:Printing

Service, Painting, Assembly,

Ultra-Sonic and Welding etc.

Our equipment:

We have a complete range of professional

equipment : EDM, CNC, Wire

Cutting, Gringing Machine, Fitting machine, 3D Measurement Machine, injection machine, etc.

Injection

press ranging from

50T to

450T, serving

customer of different needs.

Processing

a wide

range of materials

(including filled and blended material) to obtain the specified

density, color,UV stability, chemical resistance, impact

strength,flexural strength, and wear ability. Some of the those materials are:

ABS ,Acrylic ,Polycarbonate, Nylon-Filled

and Unfilled Acetal

Delrin, HDPE, LDPE, Polypropylene,

PFA, Polystyrene,

PBT, PC/ABS, PPS, PVC, POM, PMMA et.

● For polyurethane product casting we use 6 modern high-pressure machines.

● 2 Robots are operating in work area.

● If necessary 2 more machines can be added in site.

● It is possible to manufacture

small details within weight limits starting from

--0.02kg

till 10 kg

● Max part dimensions - 1.0m x 1.0m x 2.0m

● We are producing parts with IMC

(In mould coating) technology.

--Paint

is spread directly in mould.

● Feasible vaporization of

polyurethane directly into the mould in various

--layers

of thickness.